P & P Precision Designs Limited

foam welding and laminating machines

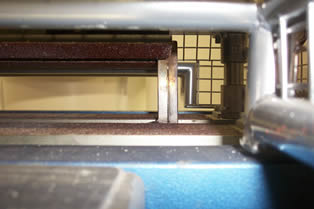

FOAM BUTT WELDING MACHINE

P&P produce 3 standard sizes

of Butt-welding machine capable of welding foam sheets of varying widths

and thickness as below:

1. Welds materials up to

1500mm wide and up to 60mm thick.

2. Welds materials

up to 1500mm wide and up to 100mm thick.

3. Welds

materials up to 2100mm wide and up to 120mm thick

The P&P Butt Welding machine has been developed to

produce a fast clean weld with no distortion to the joint surface.

The machine operates by clamping two foam sheets then compressing the

butted surfaces (edges) together.

An electrically heated blade then

traverses the length of the join welding the two sheets together to form a

length of material with a weld equivalent in strength to that of the

individual sheets.

[Click the images below to enlarge]

TECHNICAL SPECIFICATION

|

MAXIMUM FOAM THICKNESS |

60mm |

TOTAL MACHINE POWER |

1.0 KW |

|

MAXIMUM FOAM WIDTH |

1600mm |

POWER REQUIREMENTS |

230 VOLT |

|

WORKING HEIGHT |

900mm |

|

|

|

WELDING BLADE SPEED |

1 to 12 m/min |

|

OPERATING INSTRUCTIONS

FOAM LAMINATOR

The P&P Laminator operates by passing two foam sheets either side of an electrically heated blade which melts the sheet surfaces.