P & P Precision Designs Limited

foam welding and laminating machines

Foam Butt Welder » Operating Instructions

OPERATING INSTRUCTIONS

Issue 1 March 2001

P&P Precision Designs Ltd

Butt Welder Mk 2

|

INTRODUCTION |

APPENDICES: BUTT WELDING CONDITIONS

Appendix 1 LD based products

Appendix 2 EV and VA based products

Appendix 3 HD and HL based products

Butt welding is the process of

joining butt surfaces (edges) together by heat to form rolls of

material with a weld equivalent in strength to that of the

individual sheets. The machine clamps the two blocks of foam, then

compresses the edges together, then uses an electrically heated

blade that passes along the joint to weld the butt surfaces:-

i) Density: High density grades require more heat to melt an

equivalent surface area.

ii) Grade: Amount of heat required to melt a sheet surface depends

upon the melt properties of the base polymer e.g. HDPE has a higher

melting temperature range than LDPE.

iii) Butt Contact Pressure: Amount of pressure applied to the joint,

this is determined by how the machine is calibrated.

CONTENTS PART 2 CAPABILITIES OF THE P&P MK 2 BUTT WELDER

2.1 Use of Butt Welder

The machine is designed to weld Plastazote, Evazote and Supazote foam grades produced by Zotefoams.

2.2 Width

Maximum foam width of up to 1500mm

can be welded.

However there are other factors

which affect the laminated width achievable which are not related to

the design of the butt welder. The maximum width achievable depends

upon the squareness of the sheets at the edges and the alignment of

the edges as they are being fed-in.

Misalignment becomes more

important when building up long reels as the roll will not continue

straight and true along the length.

2.3 Butt Welded Reel Length

The only limit to the length of the

reel that can be produced is the difficulty of handling long reels and

ideally this requires specialised handling equipment.

2.5 Thin Sheet Foam

Altering the height of the top

clamps to accommodate foam thinner than 30mm will render the machine

potentially unsafe – The CE Mark and hence the minimum closure

distance of the clamps (25mm) has been determined using EN 294,

‘Safety Distances to Prevent Danger Zones Being Reached By Upper

Limbs’.

2.6 Rate Of Butt Welding

This is controlled by the speed of

the traversing blade, which is adjustable from the control console.

2.7 Butt Welding Temperatures

Temperature can be set in 1°C

increments up to a maximum of 550°C, which is adjusted from the

temperature controller on the console. There are specific

temperatures for particular materials, as shown in the appendices,

however, these can altered to suit particular requirements.

2.8 Weld Hold Time

Because this is similar for most

materials, ie. 5 seconds, the machine is set this way as standard.

This can be adjusted to particular requirements using the E-200 user

interface. Please refer to the ‘Electrical and Control Manual’.

CONTENTS PART 3 MACHINE OPERATION

3.1 Introduction to Operation

The

butt welder operates by

clamping two sheets of foam on either side of the electrically

heated blade. The ‘butt’ surfaces are compressed together and the

heated blade then passes across the join, welding the sheets

together.

3.1.1 General Operation

Before attempting to operate the

butt welder the user must be fully conversant with the Health and

Safety Section (Part 4) of these instructions as well as being fully

familiar with the location of the Emergency Stop button and all the

operational buttons and switches.

The Emergency Stop button isolates

power to all of the active systems and the heater blade.

The Emergency Stop button is also

used to put the machine into standby mode.

3.1.2 Sequence of Operation

a. Turn on machine and allow blade

to reach set temperature.

b. Reset the machine using the Joy-Stick.

c. Push in foam to either side of machine, ensuring foam is spread

evenly over clamp-feet-pairs and butted-up to the spacer.

d. Clamp down using Right Clamp Down Joy-Stick.

e. Carry out same procedure for Left Clamp Down.

f. Start weld sequence using Joy-Stick.

g. Allow weld sequence to complete.

h. Clamps will automatically release after a set delay.

i. Remove the two joined pieces from the machine.

j. Reset using the Joy-Stick.

3.1.3 Sheet Feeding

Foam guides are located at each side

of the machine to ensure sheets of foam line

Up. At the start of production of a new batch, these guides should

be adjusted

According to the width of foam being welded.

3.1.4 Foam Characteristics.

Successful

butt welding relies upon the contact surface maintaining even

heat transfer. The heat transfer from the blade depends upon:

i) Density High density grades require more heat to melt the

surface.

ii) Grade Heat required to melt sufficient of the material surface

depends upon the melt characteristics of the grade.

iii) Contact Surface area in contact pressure with the blade depends

upon the Gap Settings (Figure 1).

3.2 Blade temperature

3.2.1 Adjusting the Temperature

Controller

The set temperature is controlled

and adjusted by a Temperature control unit.

With power on, two temperatures are

continuously displayed, the lower being the `Desired Temperature',

the upper the actual blade temperature.

The `Desired Temperature' is

adjusted by the operator touching the front of the panel below the

displayed temperatures. The up and down buttons will illuminate and

pressing either button will change the set point value. Short

presses change the set point by single units. Long presses

accelerate the set point for large adjustments.

3.2.2 Setting the Correct Butt

Welding Temperature.

i) Temperatures must first be set

up as specified in the Appendix for the specific grade and

thickness.

ii) After start-up from cold allow heated blade to maintain set

temperature before using.

3.2.3 Using Temperatures

Higher than the Operating Temperatures

Setting the temperature slightly higher than

indicated in the Appendices may improve the weld when sheets are

uneven. However, in excess of 20°C - 68°F higher may result in

unsatisfactory weld quality.

i) The blade temperature should be kept as low as possible. In the

event of the blade becoming trapped while in contact with the blade,

the higher the temperature the greater the risk of fire.

ii) Unnecessary over-heating of material may give a thicker, darker,

more prominent weld line.

iii) Material will be more prone to sticking to the blade and uneven

melt-back will be more likely to occur; i.e., gaps and solid lumps

giving very poor quality weld.

iv) Over-heating and material sticking to the blade will result in

the emission of excess smoke and fumes.

3.3 Blade Traverse speed

3.3.1 Adjusting the Blade Speed

The 0-99 touch-dial on the operators console

controls the speed of the blade:-

The machine is normally used at full speed, although, the speed can

be lowered to suit particular requirements.

3.4 Foam Dimensional Tolerances

FOAM DIMENSIONAL TOLERANCES ARE

CRITICAL TO PRODUCING A QUALITY WELD.

IF THE FOLLOWING PRE-REQUISITES ARE NOT STRICTLY ADHERED TO, WELD

QUALITY WILL BE POOR.

The edge of the foam to be

welded requires to be sawn using a ‘band saw’.

THE SAW LINE CAN NOT DEVIATE MORE THAN 1MM FROM ONE END TO THE

OTHER.

The squareness of the saw cut

is also critical.

THE SQUARENESS OF THE SAW LINE CANNOT DEVIATE MORE THAN 1MM FROM

TOP TO BOTTOM.

CONTENTS

3.5 Butt Welding Dissimilar Materials Together

Use the conditions for the foam

with the highest set points

i.e. The highest temperature and the

slowest blade speed.

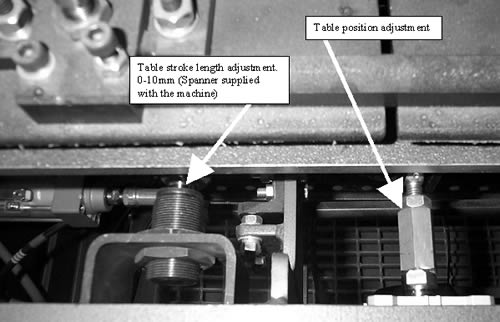

Figure 1 - Table Compression adjustments

3.6 Compression adjustment

Altering the location of the shock

absorber (Fig 1) allows the contact pressure to be altered.

The greater the distance the greater the stroke of the cylinder.

When resetting this distance ensure all four are set to exactly the

same distance.

3.6 Table position adjustment

This is adjusted at the

connection to the pneumatic cylinder. This should never need to be

altered. If adjustments are made for any reason, such as for

maintenance, ensure they are repositioned exactly. Failure to do so

could cause catastrophic damage to the machine.

CONTENTSPART 4 HEALTH AND SAFETY

Any machine can be dangerous if

improperly used.

Safe working practice is the responsibility of the user.

Note that this machine contains pneumatic clamps and a hot blade

that must not be touched.

1. This

machine must be properly and safely installed on a firm and

level base.

2. Operators must be fully

trained in the safe use of this machine.

3.

This machine must only be used for the purpose it is intended.

4. This machine incorporates fixed guards which

must not be removed.

5. All users must be

fully aware of the location of the Emergency Stop button.

6. The machine must be electrically isolated

before obtaining access to any part of the machine.

7. It is recommended that an Extraction Hood be fitted

over the machine to duct away any fumes.

8.

Under no circumstances should anybody reach inside the tunnel

guard.

9. In the event of the machine

stopping during welding and cannot be restarted normally, no

attempt should be made to clear the obstruction until it is

cooled. In the unlikely event of a fire, suitable fire

extinguishers must readily available.

10.

Operators must not wear loose clothing or items that may become

trapped in the moving parts.

11. In addition

to the above requirements local regulations on health, safety

and welfare in the workplace must be followed.

TABLE 1.1 : Traversing Blade

Butt Welder Conditions for LD based products

Materials with ‘strike-through’ (LD24LC)

have not been tested for butt welding as they were deemed unsuitable

for producing reels.

|

Product Grade |

Optimum Operating |

Speed Setting |

Vertical Clamp |

|

LD15 |

440 |

99 |

1.5 |

|

LD18 |

440 |

99 |

1.5 |

|

LD24 |

440 |

99 |

1.5 |

|

|

|||

|

|

|||

|

LD33 |

450 |

99 |

3.5 |

|

|

|||

|

LD45 |

460 |

99 |

3.5 |

|

LD60 |

480 |

99 |

3.5 |

|

LD70 |

500 |

70 |

3.5 |

CONTENTS

APPENDIX 2

TABLE 2.1 : Traversing Blade

Butt Welder Conditions for EV & VA based products

Materials with ‘strike-through’ (LD24LC)

have not been tested for butt welding as they were deemed unsuitable

for producing reels.

|

Product Grade |

Optimum Operating |

Speed Setting |

Vertical Clamp |

|

VA25 |

450 |

99 |

1.5 |

|

VA35 |

460 |

99 |

1.5 |

|

VA65 |

500 |

99 |

3.5 |

|

|

|||

|

EV30 |

470 |

99 |

1.5 |

|

EV50 |

500 |

99 |

1.5 |

|

|

|||

|

|

CONTENTS

APPENDIX 3

TABLE 3.1 : Traversing Blade

Butt Welder Conditions for HD and HL Based Products

Materials with ‘strike-through’ (LD24LC)

have not been tested for butt welding as they were deemed unsuitable

for producing reels.

|

Product Grade |

Optimum Operating |

Speed Setting |

Vertical Clamp |

|

HD30 |

500 |

99 |

3.5 |

|

|

|||

|

|

|||

|

HD115 |

|||

|

HL34 |

480 |

99 |

3.5 |

|

|

|||

|

|

CONTENTSTRADEMARKS

PLASTAZOTE, EVAZOTE and SUPAZOTE are registered trademarks of Zotefoams plc.

FOAM LAMINATOR

The P&P Laminator operates by passing two foam sheets either side of an electrically heated blade which melts the sheet surfaces.

FOAM BUTT WELDER

The P&P Butt Welding machine has been developed to produce a fast clean weld with no distortion to the joint surface.