P & P Precision Designs Limited

foam welding and laminating machines

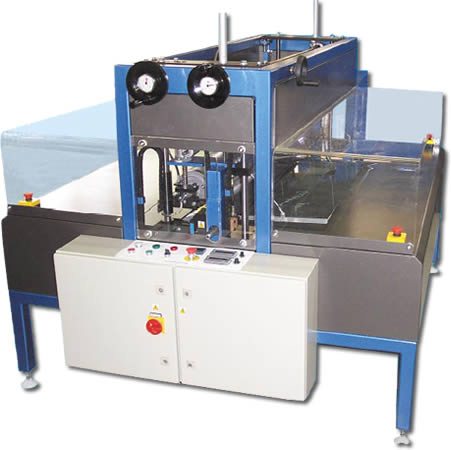

FOAM LAMINATING MACHINE

P&P produce 3 standard sizes

of Laminating machine based on the MK7 design capable of laminating foam

sheets of varying widths and thickness as below:

1.

Welds sheets up to 1300mm wide into block thickness up to 300mm.

2. Welds sheets up to 1300mm wide into block thickness up

to 500mm.

3. Welds sheets up to 1500mm wide into block

thickness up to 500mm.

The P&P Laminating machine produces

consistent, quality, repeatable welds to laminate PE foam sheets into thicker blocks.

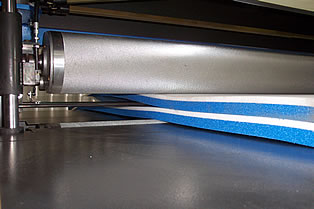

The

machine operates via a simple process which involves an operator placing

two foam sheets into the machine which pass either side of an electrically

heated blade. The heating blade melts the surface of each sheet which are

then brought into contact and compressed between two driven rollers.

The rollers then proceed to pull the sheets across the heating blade

at a controlled rate to ensure the required heat transfer is achieved.

The adjustable spacing between the driven rollers controls the amount

of pressure exerted on the sheets.

The melted sheet surfaces are

forced together by the drive rollers where solidification takes place to

form a thicker block with a laminated bond equivalent in strength to that

of the individual sheets.

[Click the images below to enlarge]

TECHNICAL SPECIFICATION

|

MAX LAMINATED BLOCK SIZE |

300mm |

KNIFE WIDTH |

1600mm |

|

ROLLER SPEED |

1 - 8 m/min |

MAX CUSTOMER FUSE SIZE |

30 AMP |

|

ROLLER WIDTH |

1500mm |

WEIGHT |

750 KG |

|

MAX LOWER ROLLER TO KNIFE |

250mm |

TOTAL MACHINE POWER |

8.5 KW |

|

MAX UPPER ROLLER TO KNIFE |

100mm |

POWER REQUIREMENTS |

380/400 VOLTS 50/60Hz |

PDF DOCUMENTS

1300w x 300h Laminator Specification

1300w

x 500h Laminator Specification

1500w x 500h

Laminator Specification

OPERATING INSTRUCTIONS

FOAM BUTT WELDER

The P&P Butt Welding machine has been developed to produce a fast clean weld with no distortion to the joint surface.